More questions?

Explore more resources to help you reach all your goals:

How do I decide if something should be kept in stock?

How do I decide if something should be kept in stock?

This is the most fundamental question asked by many operations management professionals…

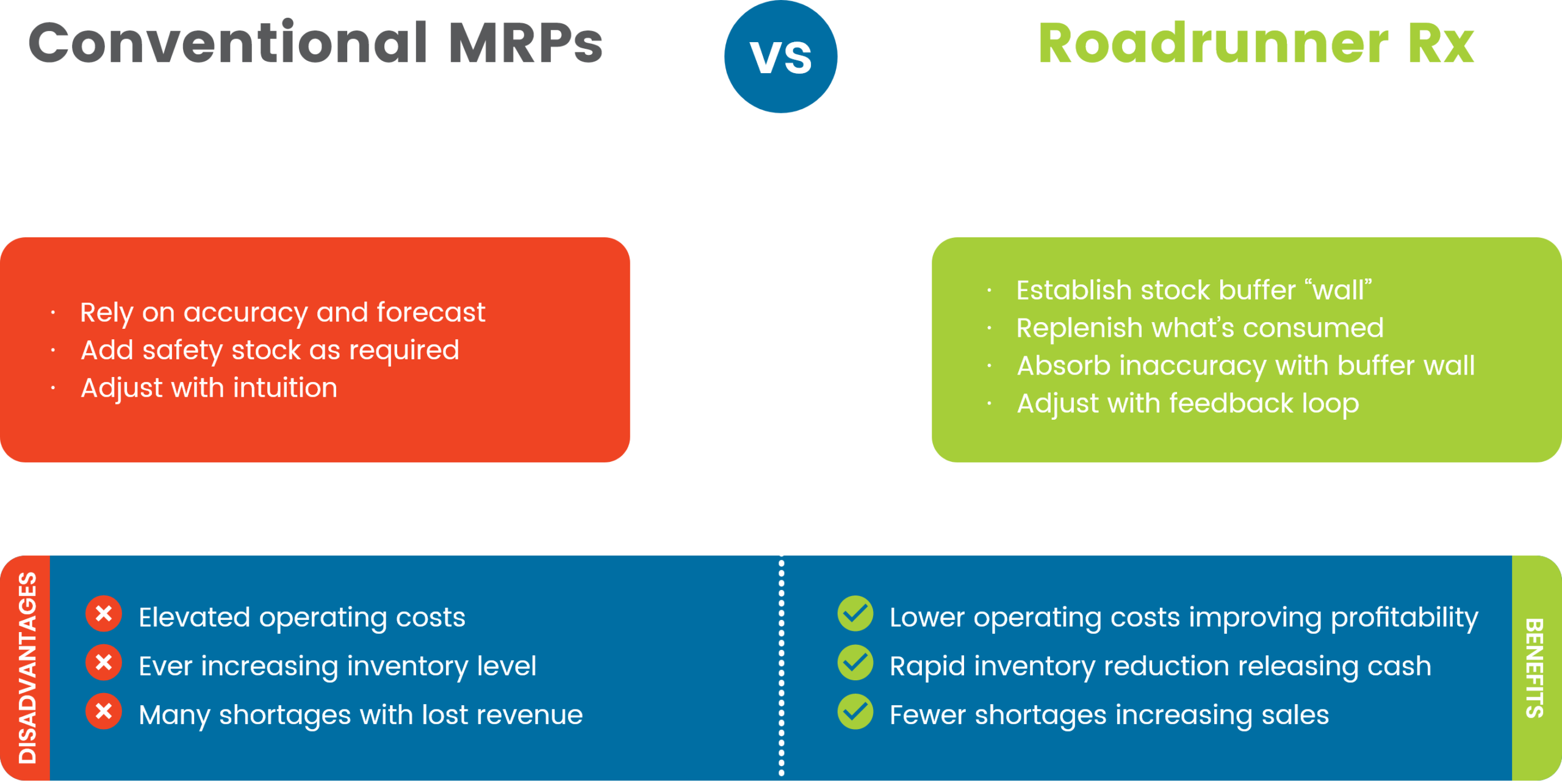

Some business people believe that make to order mode of operation is the most efficient way of doing business. In most cases however, there is nothing further from the truth. Small inventory levels provide stability for your manufacturing floor and your overall supply chain.

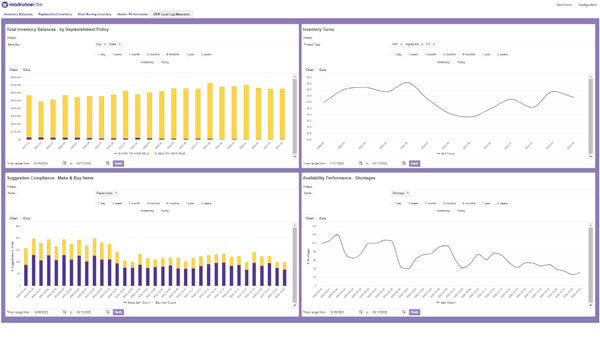

roadrunner Rx provides visibility of any item transaction frequency, its related lead times, consumption level fluctuations and much more when deciding what to stock and what not to stock.

In addition, roadrunner generates suggestions based on these factors… However, new product introductions and end of life items require additional attention from your team. Rx IMS guarantees up to date decisions on which items should be stocked or handled to order.

How do I know which items to buy/make today?

How do I know which items to buy/make today?

Well, roadrunner Rx is constantly generating both What to Make and What to Buy requirements. We have the ability to look at all Purchase to Stock & Purchase To Order as well as Manufactured to Stock & Manufactured To Order items. roadrunner’s suggestions are highly accurate, because unlike typical forecast driven MRP, they are mainly based on actual consumption and confirmed demand. In addition, roadrunner Rx automatically identifies current stock shortages to ensure your product availability.

This quantity to be purchased or manufactured will be shown in the Buy This or Make this column on the What to Buy or What to Make Screen.

Once the suggested quantity is greater than the Minimum Order Quantity or an MOQ, the suggestion to make or buy gets created. The best news with our Rx IMS is you don’t have to worry about the complexity of this screen and underlying supply and demand algorithm because the output of the make and buy requirements will be sent directly to your ERP system for you to act on.

Which Work Orders / Purchase Orders should I push out or cancel?

Which Work Orders / Purchase Orders should I push out or cancel?

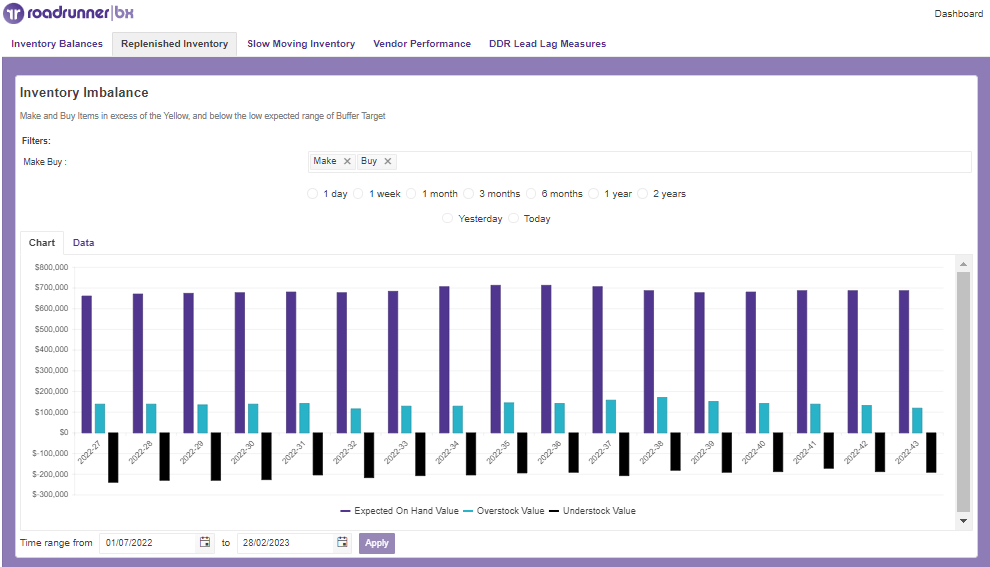

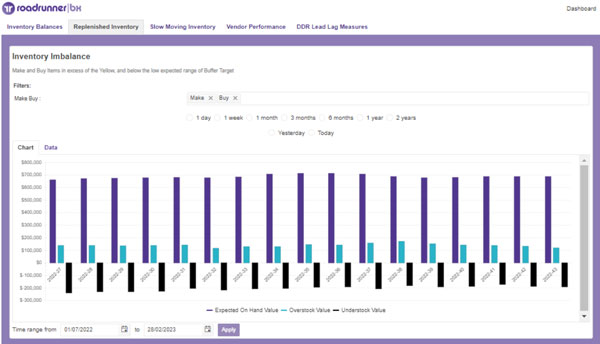

Quite often we wonder, have we already placed too many orders?

Well, roadrunner Rx provides real time visibility of both Work order & Purchase order requirements. The column “Over Ordered Quantity” identifies the overages within a supply lead time on an item by item basis.

Rx IMS provides a monetary value in which a given item is over ordered based on current supply vs. current demand. Our service will automatically generate a report that identifies value and duration of each item overage for your team to act on.